Sealing Solutions for Hydrogen Applications

Hydrogen has a very high potential in the future as an alternative to existing energy sources because it is a clean and renewable energy source. It also has smaller molecular size and high diffusion rate compared to other gases. It is used in different application areas such as fuel cell systems, hydrogen turbines, process gas and intermediate products in the chemical industry.

Hydrogen has a very high potential in the future as an alternative to existing energy sources because it is a clean and renewable energy source. It also has smaller molecular size and high diffusion rate compared to other gases. It is used in different application areas such as fuel cell systems, hydrogen turbines, process gas and intermediate products in the chemical industry.

Hydrogen is a colorless, odorless and volatile molecule that reacts with air and poses an explosive risk. Sealing elements have an important role to reduce this risk in the production, transportation, storage, consumption stages and other applications of hydrogen.

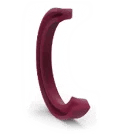

Sealing elements are components that prevent hydrogen from escaping and prevent it from spreading to its surroundings. These elements are used to ensure environmental safety, protect worker safety and support the efficient operation of energy systems by minimizing the leakage of hydrogen. Here are some of the important roles of seals in hydrogen production processes:

Safety: Because hydrogen is lighter than air, in the event of a leak it can rise rapidly and spread into the environment. This can increase the risk of explosion. Seals ensure plant safety by minimizing these leaks.

Efficiency: Preventing leaks in hydrogen production processes can improve production efficiency. Hydrogen lost through leaks can result in energy and cost losses.

Environmental Protection: It is possible for hydrogen to diffuse into the environment, mix with the atmosphere and therefore have a greenhouse gas effect. Seals minimize these negative environmental impacts and ensure a sustainable energy production process.

Worker Health: Sealing elements are used to ensure the safety of workers. Hydrogen leaks should be prevented to reduce health risks to workers.

Kastas Sealing Technologies offers products with low hydrogen permeability tested to ZP5101 by the DVGW organisation. NB7006 is compatible with H2 and oxygen and offers superior resistance to rapid gas decompression due to its low permeability. NB7006 is EN 549:2019 B2/H3 class certified and is one of the Kastas products that meets the requirements of ZP 5101:2021. NB8026 is compatible with H2 and oxygen, has very low permeability, offers superior resistance to rapid gas decompression and meets the requirements of ZP 5101:2021.

You can contact us for more questions and solutions for your specific application areas!